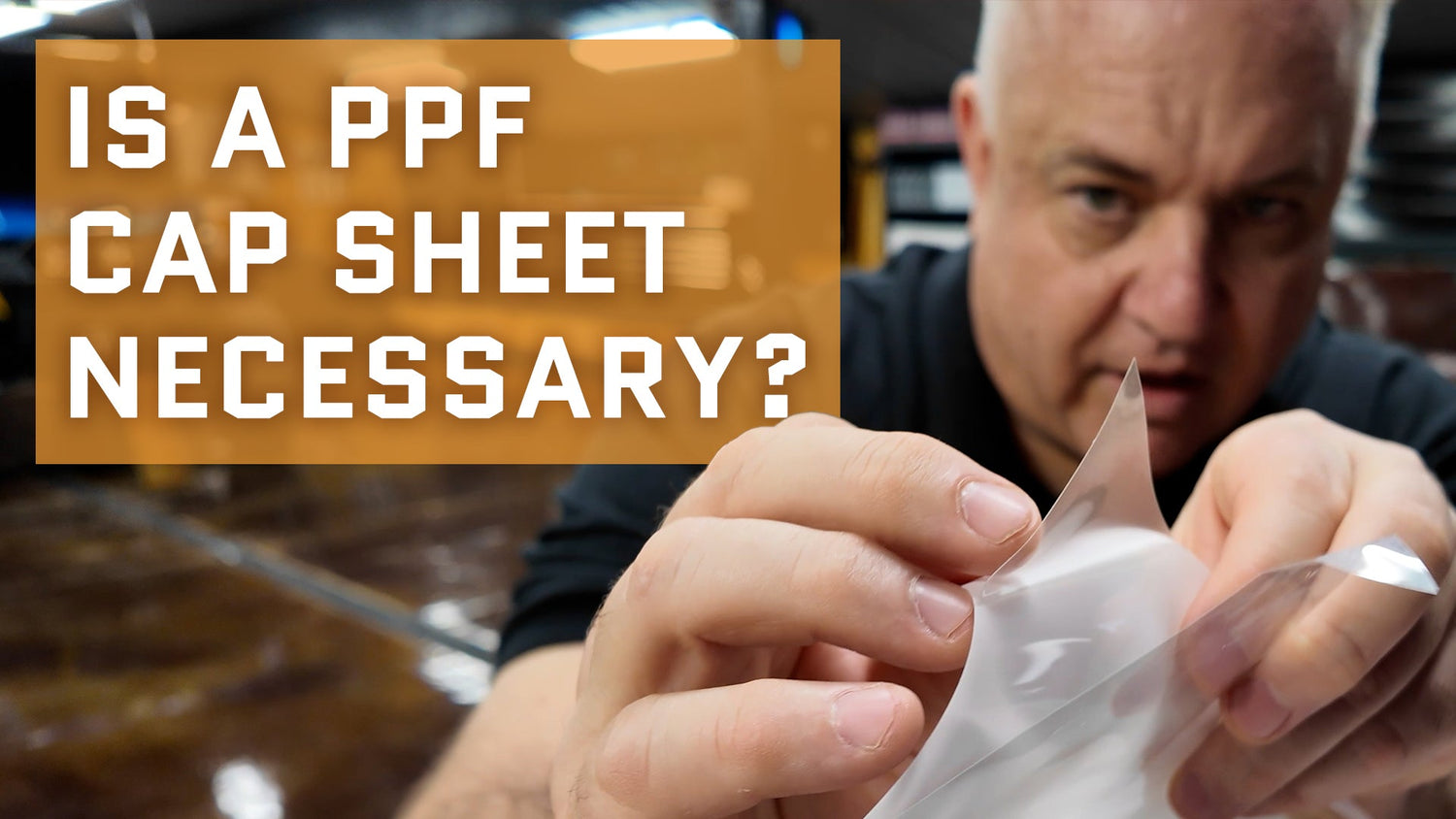

Is A Cap Sheet Necessary for Paint Protection Film (PPF)?

When it comes to paint protection film, like our FlexGuard, there’s one key decision to make: do you order it with a cap sheet or without? While it might seem like a small detail, understanding the role of a cap sheet can save you time, frustration, and even money in the long run.

What is a Cap Sheet?

A cap sheet is a thin protective layer that sits on top of the paint protection film (PPF). Think of it as an extra shield during shipping and handling. When you order PPF with a cap sheet, the product comes in three layers:

- The Backer Sheet: The bottom layer that protects the adhesive.

- The Paint Protection Film: The main product you’ll install on a vehicle.

- The Cap Sheet: The top layer that protects the film during shipping and handling.

Pros and Cons of a Cap Sheet

Convenience Without a Cap Sheet

Ordering PPF without a cap sheet can be convenient because you won’t need to remove it before installation. Removing the cap sheet adds an extra step and can sometimes cause static electricity, which may affect your plotter. While spraying a light mist can deactivate static, many installers overlook this trick. For some, skipping the cap sheet entirely feels like the simpler option.

Advantages of a Cap Sheet

Despite the added step, a cap sheet offers several key benefits that can make it worthwhile:

-

Protection During Shipping

Shipping can be tough on paint protection film. Ideally, rolls should be stored vertically, but sometimes they’re stored horizontally or rest unsupported on shelves. Over time, this can cause pressure distortions that affect the adhesive layers and even the film’s core. A cap sheet acts as a buffer, reducing the risk of damage during shipping and storage. -

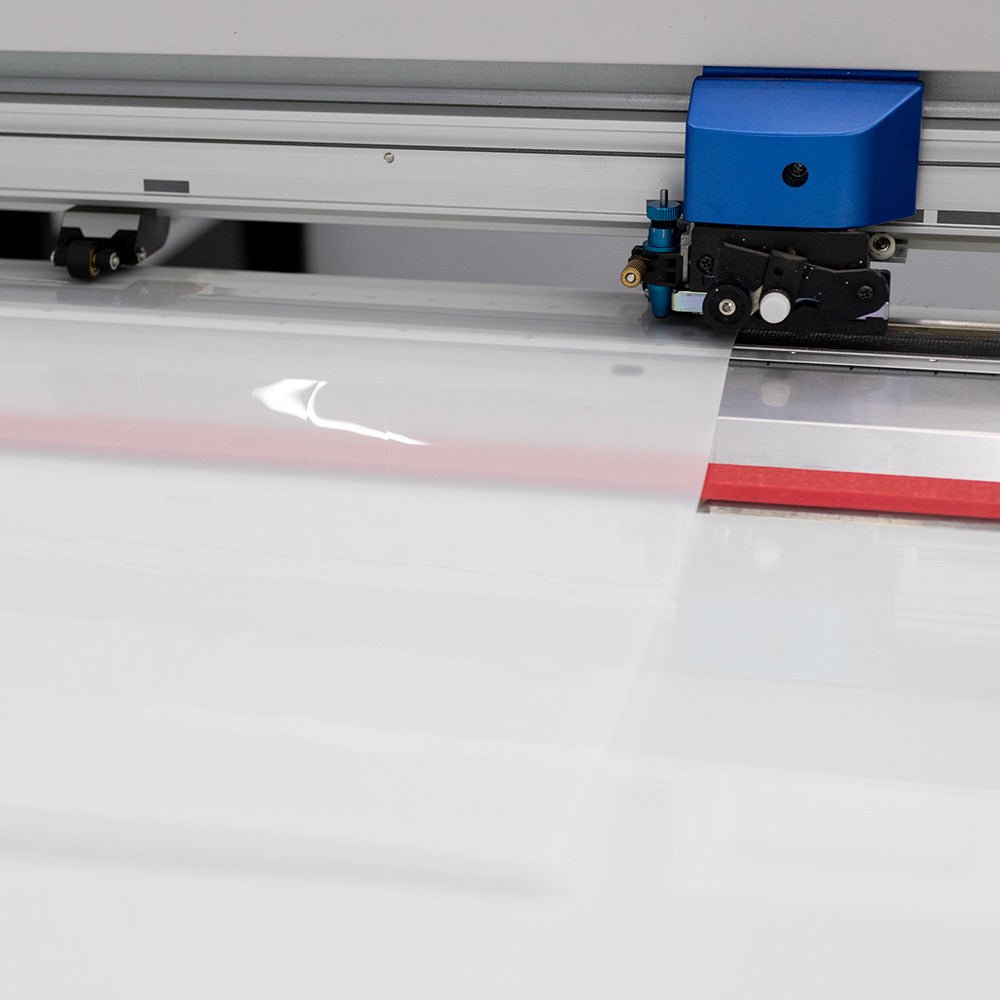

Prevention of Distortion on Roller Bars

Installers often load PPF onto roller bars before cutting patterns. If you accidentally leave the roll on the bars overnight, the weight can create repeating distortion patterns throughout the roll. Without a cap sheet, this could ruin an entire roll, leaving you with limited usable material for smaller jobs like door cups or edge guards. A cap sheet provides a second layer of protection, giving you a “second chance” in these situations. -

Enhanced Visibility for Cutting and Weeding

High-quality PPF is incredibly clear, which can make it difficult to see where you’ve cut a pattern. A cap sheet improves visibility, making it easier to weed the pattern and prepare for installation. While some argue that a cap sheet might dull your blade slightly faster, the cost of replacement blades is minimal compared to the convenience of accurate cuts.

Why Cap Sheets are Gaining Popularity

Although the industry started with a preference for cap sheet-free PPF, cap sheets are becoming increasingly popular. They’re not difficult to remove and offer significant benefits during shipping, storage, and installation. For installers handling top-tier products, the added protection and ease of use can make a noticeable difference.

Final Thoughts

Choosing whether to order our FlexGuard premium paint protection film with or without a cap sheet depends on your workflow and priorities. If convenience is key and you want to skip the extra step, you might prefer no cap sheet. But if you value added protection, better cutting visibility, and peace of mind during shipping and handling, a cap sheet is worth considering.

At Flexfilm, we believe in providing you with the information you need to make the best decision for your business. Whether you choose a cap sheet or not, understanding its purpose ensures you’re making an informed choice that aligns with your needs. If you’re still unsure, reach out to us—we’re here to help!

Description

FlexGuard is a durable, nearly invisible urethane barrier that protects your vehicle’s paint from debris, rocks, bugs and more. Features include:

-

Self Healing: Minor scratches just disappear

-

Water Resistant: The hydrophobic surface resists stains and sheds water

-

Scratch & Debris Protection: Durable 8 Mil urethane film protects your vehicle from the road

-

Reduces UV Oxidation: Reduce damage from the sun like ultraviolet oxidation or paint fading and cracking

-

Save Money: Protect the re-sell value of your vehicle and maintain that new car feeling

-

Easy To Install: Flexible product that conforms to any vehicle's shape.

- Two Options: available in clear or matte

Protect Your Investment

Guard Against The Road

We Got You Covered

FlexGuard is backed by a 10-year manufacturer warranty. Drive with peace of mind knowing that FlexGuard will protect your vehicle for the future. You can view additional warranty information here. You are covered against defects such as:

- Yellowing

- Staining

- Cracking

- Blistering

- De-laminating

Coverage Options

Consult your local professional installer to see what option is best for you and your vehicle.

Choose Your Guard

With FlexGuard, the possibilities are endless. Protect your car, truck, camper, motorcycle and more. From a full vehicle wrap that guards the entire vehicle to protecting the most defenseless areas that are more prone to chips and scratches like the leading edges of hoods and fender and also bumper covers.

Maintenance & Care

To ensure the longevity of FlexGuard, please adhere to the instructions below. Failure to adhere to the maintenance and care instructions can void the product's warranty.

-

Every 3-4 months, use a non-abrasive wax or sealant application to ensure longevity to product.

- Do not use abrasive drying materials during drying or waxing.

- Do not wax or wash vehicle for 7 days after FlexGuard installation.

- Prevent staining by removing all bugs, sap, tar and other substances as soon as possible.

- Do not use polishing compounds, clay bars or waxes that contain dyes or abrasives.

- Do not use abrasive sponges or wash mitts during washing.

- Avoid using a high pressure sprayer too close to the vehicle.

- Do not use solvent based bug and tar removers.

Dealer Rewards

Start earning points that can be applied as store credit on your next online purchase.

Order Online 24/7

Shop our products online and check out anytime, 24/7, from anywhere!

Call To Order

Call us directly to place your order during business hours, Monday - Friday, 8:00 AM - 4:00 PM CST.