Built From Experience

With nearly 40 years of industry experience, we understand what it takes to run a successful window tinting business. This expertise allows us to anticipate our customers' needs like no one else. We are committed to supporting and collaborating with our customers to ensure their success.

"I’ve got 44 years experience tinting and throughout that time I’ve put hands on every brand of film on the market. I can honestly say Flex is the best film I’ve installed plus my customers love the clarity it has."

Scott Little, TintMan

Our Mission

At Flexfilm, our business model stands out for its uniqueness. Unlike many others in our industry, we offer top-tier, professional-grade products without the burden of buy-ins or quotas. Our products not only match but often surpass those of major brands in the industry. This is the essence of Flexfilm – providing an open invitation to veteran installers and newcomers in the industry seeking the finest window film solutions.

No barriers

We don't impose quotas or demand costly buy-ins to start our parternship.

Get Rewarded

Start earning points that can be applied as store credit on your next online purchase.

Fast, free shipping

Enjoy free shipping on orders over $750 and same-day shipping on orders placed before 12:30 PM CST.

Tint now, pay later

Pick the option that works for you and your budget. Just select Shop Pay at checkout.

Our History

Flexfilm started humbly in a driveway in 1987 when Ralph Van Pelt tinted his Nissan Pulsar. Soon after, Window Tinting by Ralph Van Pelt was born in that same driveway where he honed his skills and learned the trade.

During the 1990s, Ralph partnered with local stereo shops, working with them to create and manage their window tinting service. In 1996, Ralph found success in his first shop, Special FX. Using all his wisdom and experience, Ralph ventured into the manufacturing and distribution of window film, opening Flexfilm's doors in 2011, and Flexfilm has been dedicated to offering the best quality products ever since.

At Flexfilm, our business model stands out for its uniqueness. Unlike many others in our industry, we offer top-tier, professional-grade products without the burden of buy-ins or quotas. Our products not only match but often surpass those of major brands in the industry. This is the essence of Flexfilm – providing an open invitation to veteran installers and newcomers in the industry seeking the finest window film solutions.

How do I buy from you?

We don't impose quotas or require costly buy-ins to start our partnership. Whether you're a seasoned professional installer or a weekend DIY enthusiast, we are here to supply you with the products you need. Place your order on our website 24/7 or by phone during business hours. You can check out as a guest if you're in a hurry, or create an account to take advantage of our dealer rewards program. The choice is yours, and we're here to support you! When you're ready to order, simply add the products to your cart and proceed to checkout.

Damaged, lost, or stolen order?

If you purchased Route package protection at checkout, please file a claim with the Route team by clicking here. If not, please contact Flexfilm for assistance.

What's your return policy?

Need to return a product or curious about our return policy? Click here to review the details.

What's your shipping policy?

In a hurry for your product? Curious about qualifying for free shipping or same-day shipping? Click here to check out our shipping policy to learn more.

What is your 2024 holiday schedule?

As always, you can place an order any time of the day on our website. Any orders placed while we are closed will be shipped out the next business day.

- Coming soon...

"Ive been setup with Flexfilm for almost a year, and I wont go back to any other product. I have use them all in copious amounts, security, hurricane, solar and architectural. Flexfilm is the King!"

Dennis Klotz

"To be honest I am extremely happy since switching to Flexfilm. As an installer I think it is a very high quality product and from my customers stand point they are extremely happy with the final result too."

Craig Haney

"Flexfilm is the best hands down for the prices and service. You can't find anything better out there..."

Sean Wahlberg

“Flexfilm allows me to quickly and easily order film and tools online with no phone calls or middle man. I also like the fact that you have your film performance data readily available on the website. I appreciate the usually fast shipping also.”

Richard Remelius

"Been using it for 2+ years and I love it shrinks like a dream and I have never had a problem with it at all."

Bradley Jones, The Tint Plug

"I have been using your film for almost 7 years now and never had a problem."

Zane Wilson

See Our Films In Action✨

@flexfilmtint

Don’t just take our word for it—check out the real-world projects our awesome partners have pulled off with our products! Follow us for fresh inspiration, and see how our solutions can level up your next DIY project or even boost your shop’s game. You might even be our next feature—just tag @flexfilmtint on Instagram or Facebook!

The Latest With Ralph and Flexfilm

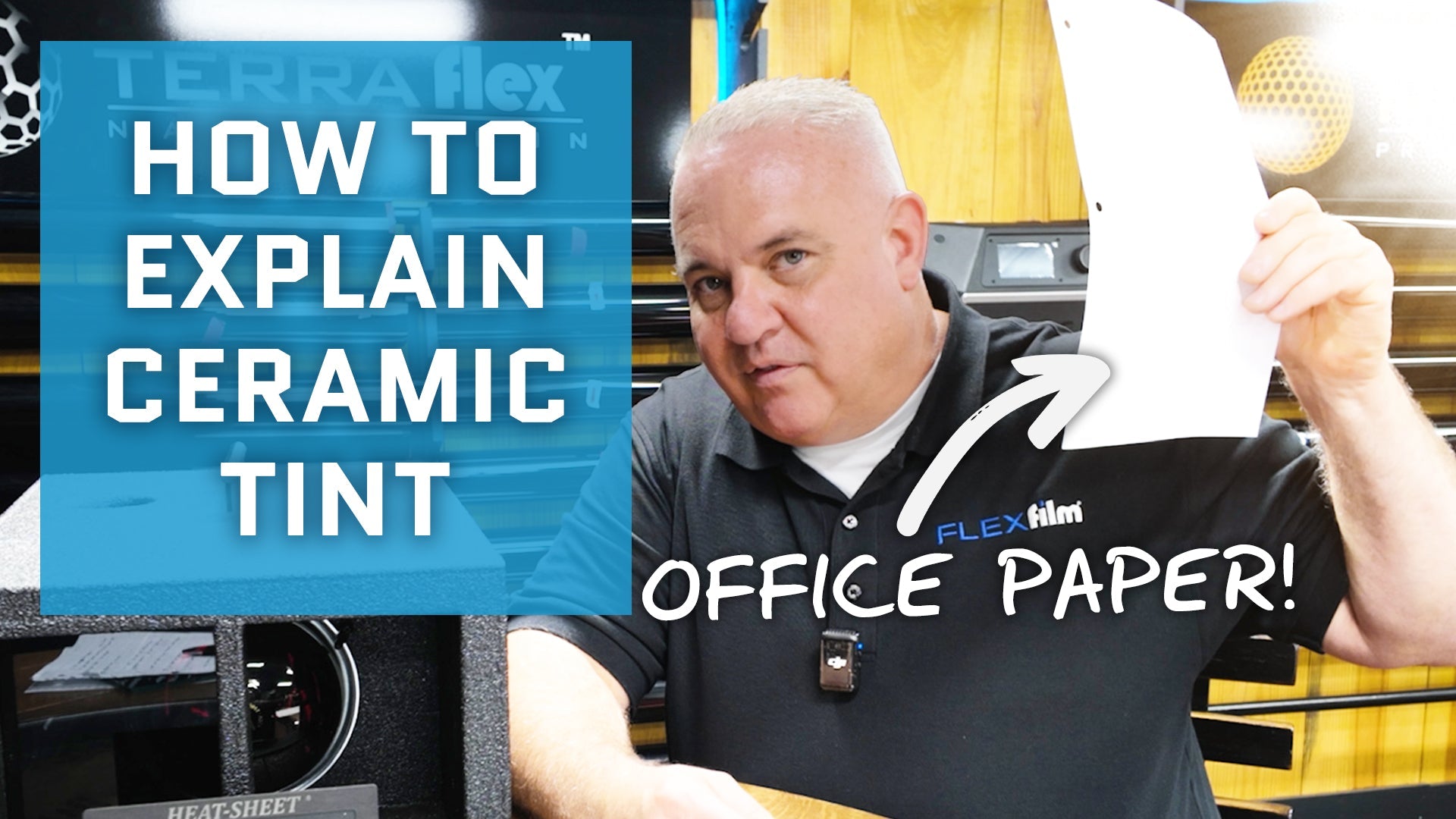

How to Explain Ceramic Tint to Customers (Using Paper)

Most customers don’t care about IR numbers or TSER charts. They just want to know if ceramic tint is worth it. In this post, Ralph explains a simple method to prove the value of ceramic window film...

Understanding Pressure Sensitive Adhesive

Not all window film installs the same, and it usually isn’t the film’s fault. This guide explains pressure sensitive adhesive, why some films bond faster than others, and how understanding adhesive...

Don't Overpay For Big Brand's Window Tint

Does paying more for big brand ceramic window tint actually deliver better results? This article breaks down a real-world test that shows how close entry-level and big brand ceramic films really ar...

Dealer Rewards

Start earning points that can be applied as store credit on your next online purchase.

Order Online 24/7

Shop our products online and check out anytime, 24/7, from anywhere!

Call To Order

Call us directly to place your order during business hours, Monday - Friday, 8:00 AM - 4:00 PM CST.