Dualflex | Dual Reflective Series

Tax excluded. Shipping calculated at checkout

on orders placed before 12:30PM CST*

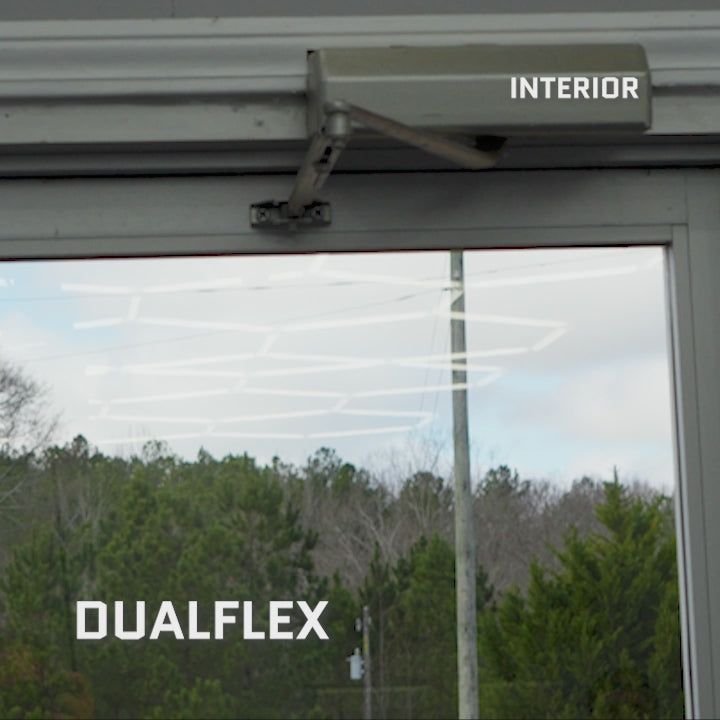

Dualflex

Dual Reflective Series

Dualflex’s outer metallized layer works by reflecting the solar energy before it transmits through the glass while the inner layer uses low reflective carbon to offer maximum visibility. Hands down, dual reflective film is the most popular architectural film technology in the industry because of its affordability, compatibility with all glass types, and aesthetics. Constructed with an inner layer of carbon and an outer layer of vapor coated aluminum, Dualflex offers a natural, moderately reflective layer that produces an attractive appearance on any storefront or home. Carbon brings to the table no fading or color change unlike similar products in the industry that are constructed with dye. Dualflex offers an inviting, warm appearance that is suitable for homes and storefronts.

Benefits

- Very popular

- Mirror-like metallized outer layer

- High visibility carbon inner layer

- One-way daytime privacy

- Exceptional heat reflectance

- UV protection

- High IR rejection

- High glare reduction

- Neutral gray color and appearance

- Suitable for most glass type

5%

- Highly reflective metallized outer layer

- High visibility carbon inner layer

- Dry adhesive

15%

- Reflective metallized outer layer

- High visibility carbon inner layer

- Dry adhesive

25%

- Moderately reflective metallized outer layer

- High visibility carbon inner layer

- Dry adhesive

35%

- Minimally reflective metallized outer layer

- High visibility carbon inner layer

- Dry adhesive

Download our digital informational booklet which contains product details, spec data, glass compatibility information, and more. View PDF

Note: Window films can have slight color variations between rolls. Please exercise caution when matching projects that involve different rolls.

Performance Data

Safety Considerations

Considerations Before Installation of Flat Glass

There are many considerations an installer needs to make before installing flat glass on a project. Please read and familiarize yourself with the considerations below as well as the film-to-glass compatibility chart to ensure a flawless installation you can enjoy for the years to come.

Shading Considerations

Understanding the nuances beyond basic film-to-glass compatibility is key for successful window tinting, especially considering the impact of external shading. Shading from trees, buildings, or other structures can change throughout the day, creating a risk of thermal fracture where shaded and sunlit areas of the glass meet. This can increase the likelihood of the glass breaking due to thermal stress.

To avoid such issues, a detailed evaluation of the window's exposure to light and shade over the day is essential. This helps in choosing the right tinting material that suits the window's thermal conditions, preventing potential damage. Consulting our graphic below can also highlight risky shade patterns, aiding in effective tint planning. These steps ensure the longevity of the tinted window while keeping the building's occupants safe and comfortable.

Window Characteristics

Choosing the right type of glass is crucial for safely applying window tint, requiring an evaluation of the glass's specific characteristics. It's essential to determine whether the glass is single or double pane and its category—annealed, laminated, or tempered—each with unique considerations for tinting.

For single pane windows, understanding if the glass is annealed (prone to thermal stress but generally safe for tinting), laminated (offering safety and UV protection), or tempered (able to handle more thermal stress, ideal for variable temperatures) is key.

With double pane windows, recognizing the specific glass type becomes even more critical due to the added complexity from the airspace between the panes, which influences thermal stress, particularly under varied temperatures.

Other factors impacting tint installation include the window's size and thickness, which affect its strength and thermal stress capacity; the building's age, indicating possible pre-existing window issues; and the window's orientation, as direct sunlight increases thermal stress risks. Any previous glass failures should be examined for insights into potential vulnerabilities that tinting could worsen.

A thorough assessment of the glass type, window specifics, building conditions, and historical performance is vital for the safe, effective application of window tint, ensuring it enhances the building's efficiency, privacy, and aesthetics.

Environmental Variables

Design Winter Temperature is crucial for choosing the right window film, as it must endure the local minimum temperatures without losing effectiveness or damaging the glass. Films not designed for the locale's winter conditions might become brittle or fail to insulate properly.

Altitude affects window film due to changes in barometric pressure. At higher elevations, lower air pressure can increase stress on double-pane windows, potentially leading to damage when combined with the thermal effects of window film. Selecting a film that can withstand these pressures is vital.

Adjacent Reflecting Surfaces, such as water, other buildings, or snow, can increase sunlight and heat reflection, raising the risk of thermal stress on the glass. It's important to consider these factors by choosing films with high heat rejection or altering the environment to reduce reflection, ensuring the film's effectiveness and the glass's integrity.

Low-Emissivity (Low-E) Windows

When installing window film on Low-E (low-emissivity) windows, it's crucial to consider several factors due to Low-E glass's special features designed to improve energy efficiency by reflecting infrared light and retaining heat. Key considerations include:

- Compatibility with Low-E Coatings: Choose a window film compatible with the Low-E coating to maintain its energy-saving benefits. Some films can enhance, while others might undermine, these properties.

- Thermal Stress Risk: Adding film can increase thermal stress, potentially causing glass breakage due to temperature differences across the glass surface. Select a film that manages heat transmission without creating significant thermal imbalances.

- Warranty Considerations: Ensure installing window film doesn't void the window's manufacturer warranty. Check warranty terms and consult with both window and film manufacturers.

- Visual Aesthetics and Light Transmission: The addition of window film can alter window appearance and the amount of natural light entering. The impact on building aesthetics and interior lighting should be considered.

- Energy Efficiency Goals: Aim for a window film that complements the Low-E glass's energy efficiency, enhancing without compromising its functionality.

Consulting a professional installer experienced in both Low-E glass and window film is recommended to navigate these complexities, ensuring the film supports the window's performance and the building's energy efficiency and comfort effectively.

Heating & Cooling Vent Locations

The location and orientation of heating and cooling vents are crucial for the safe and effective use of window film on flat glass surfaces. Vents directing air towards the glass can cause temperature variations, potentially leading to thermal stress. Heating vents can create hot spots by warming a cooler glass surface, while cooling vents can induce thermal shock by cooling a heated glass surface. These temperature changes, especially under the added stress from solar energy absorption and window film, can compromise the glass and film's integrity.

Positioning vents away from the glass helps maintain a consistent temperature across the window, reducing thermal stress risks and supporting the durability of the glass and film. Evaluating the heating and cooling system's layout, including air flow direction and vent proximity to windows, is vital. Adjusting vent direction or using diffusers to avoid direct air flow onto the glass can create a stable environment for window film application.

Careful management of heating and cooling vent locations and orientations is key to minimizing thermal stress and maximizing the window film's benefits without risking the window's structural integrity.

At Flexfilm, we strive to offer comprehensive support and guidance; however, we cannot account for every unique variable in each individual project. Consequently, Flexfilm assumes no responsibility for issues arising from incomplete assessments or improper installation practices.

Glass Compatibility

Shipping & Returns

Shipping

Orders placed by 12:30 PM CST will be shipped out the same day. Orders placed after this time will be shipped on the next business day. We offer both standard and expedited shipping options within the United States. Exclusions apply.

Enjoy free shipping on orders over $750.

United States Shipping Options (Restrictions may apply):

- UPS® Ground

- UPS 3 Day Select®

- UPS 2nd Day Air®

- UPS Next Day Air Saver®

- UPS Next Day Air®

- UPS Next Day Air® Early

For more details and restrictions, please refer to our full shipping policy.

Returns

Films

- 30-day return policy.

- Buyer covers return shipping (deducted from refund if originally free).

- Up to a 20% restocking fee.

- All materials must be returned.

- Used rolls may receive a partial refund.

Pre-Cut Patterns

- No returns or refunds for custom films.

Tools & Equipment

- All sales are final.

- We replace wrong or defective items at our expense.

- No refunds for buyer’s remorse, misuse, or damage from lack of skill.

Plotters

- 30-day return if in re-sellable condition and original packaging.

- Overseas customers pay return shipping.

- Up to a 20% restocking fee may apply.

For more details and restrictions, please refer to our full return and refund policy.

Disclaimer

Glass Safety Assessment

We offer professional-grade flat glass films designed for experienced installers. However, we’re unable to determine which specific Flexfilm product is safe for your particular window or glass type. Because we operate online, we don’t have access to the full range of variables needed to make an accurate, case-by-case assessment.

We strongly recommend consulting a local professional installer who can evaluate your glass in person. For liability reasons, we only provide official film-to-glass approvals to Flexfilm Dealers.

That said, you're welcome to reference our glass compatibility chart and supporting materials to help guide your decision—but please note that we cannot make a final recommendation ourselves.

Unprofessional or DIY Installation

Please be aware that applying our flat glass film through unprofessional or do-it-yourself (DIY) methods does not come with a guarantee of success or assurance against potential future complications. While DIY installation might seem cost-effective and convenient, the absence of professional expertise can lead to improper application. This might result in issues such as bubbles, peeling, uneven tinting, performance discrepancies, or even damage to the glass itself. Furthermore, any future problems arising from a non-professional installation might not be covered under our product warranty. To ensure the best results and maintain your product warranty, we highly recommend opting for installation by a qualified professional. This approach not only secures a successful outcome but also safeguards against the risk of avoidable issues down the line.

Considerations Before Installation of Flat Glass

There are many considerations an installer needs to make before installing flat glass on a project. Please read and familiarize yourself with the considerations below as well as the film-to-glass compatibility chart to ensure a flawless installation you can enjoy for the years to come.

Shading Considerations

Understanding the nuances beyond basic film-to-glass compatibility is key for successful window tinting, especially considering the impact of external shading. Shading from trees, buildings, or other structures can change throughout the day, creating a risk of thermal fracture where shaded and sunlit areas of the glass meet. This can increase the likelihood of the glass breaking due to thermal stress.

To avoid such issues, a detailed evaluation of the window's exposure to light and shade over the day is essential. This helps in choosing the right tinting material that suits the window's thermal conditions, preventing potential damage. Consulting our graphic below can also highlight risky shade patterns, aiding in effective tint planning. These steps ensure the longevity of the tinted window while keeping the building's occupants safe and comfortable.

Window Characteristics

Choosing the right type of glass is crucial for safely applying window tint, requiring an evaluation of the glass's specific characteristics. It's essential to determine whether the glass is single or double pane and its category—annealed, laminated, or tempered—each with unique considerations for tinting.

For single pane windows, understanding if the glass is annealed (prone to thermal stress but generally safe for tinting), laminated (offering safety and UV protection), or tempered (able to handle more thermal stress, ideal for variable temperatures) is key.

With double pane windows, recognizing the specific glass type becomes even more critical due to the added complexity from the airspace between the panes, which influences thermal stress, particularly under varied temperatures.

Other factors impacting tint installation include the window's size and thickness, which affect its strength and thermal stress capacity; the building's age, indicating possible pre-existing window issues; and the window's orientation, as direct sunlight increases thermal stress risks. Any previous glass failures should be examined for insights into potential vulnerabilities that tinting could worsen.

A thorough assessment of the glass type, window specifics, building conditions, and historical performance is vital for the safe, effective application of window tint, ensuring it enhances the building's efficiency, privacy, and aesthetics.

Environmental Variables

Design Winter Temperature is crucial for choosing the right window film, as it must endure the local minimum temperatures without losing effectiveness or damaging the glass. Films not designed for the locale's winter conditions might become brittle or fail to insulate properly.

Altitude affects window film due to changes in barometric pressure. At higher elevations, lower air pressure can increase stress on double-pane windows, potentially leading to damage when combined with the thermal effects of window film. Selecting a film that can withstand these pressures is vital.

Adjacent Reflecting Surfaces, such as water, other buildings, or snow, can increase sunlight and heat reflection, raising the risk of thermal stress on the glass. It's important to consider these factors by choosing films with high heat rejection or altering the environment to reduce reflection, ensuring the film's effectiveness and the glass's integrity.

Low-Emissivity (Low-E) Windows

When installing window film on Low-E (low-emissivity) windows, it's crucial to consider several factors due to Low-E glass's special features designed to improve energy efficiency by reflecting infrared light and retaining heat. Key considerations include:

- Compatibility with Low-E Coatings: Choose a window film compatible with the Low-E coating to maintain its energy-saving benefits. Some films can enhance, while others might undermine, these properties.

- Thermal Stress Risk: Adding film can increase thermal stress, potentially causing glass breakage due to temperature differences across the glass surface. Select a film that manages heat transmission without creating significant thermal imbalances.

- Warranty Considerations: Ensure installing window film doesn't void the window's manufacturer warranty. Check warranty terms and consult with both window and film manufacturers.

- Visual Aesthetics and Light Transmission: The addition of window film can alter window appearance and the amount of natural light entering. The impact on building aesthetics and interior lighting should be considered.

- Energy Efficiency Goals: Aim for a window film that complements the Low-E glass's energy efficiency, enhancing without compromising its functionality.

Consulting a professional installer experienced in both Low-E glass and window film is recommended to navigate these complexities, ensuring the film supports the window's performance and the building's energy efficiency and comfort effectively.

Heating & Cooling Vent Locations

The location and orientation of heating and cooling vents are crucial for the safe and effective use of window film on flat glass surfaces. Vents directing air towards the glass can cause temperature variations, potentially leading to thermal stress. Heating vents can create hot spots by warming a cooler glass surface, while cooling vents can induce thermal shock by cooling a heated glass surface. These temperature changes, especially under the added stress from solar energy absorption and window film, can compromise the glass and film's integrity.

Positioning vents away from the glass helps maintain a consistent temperature across the window, reducing thermal stress risks and supporting the durability of the glass and film. Evaluating the heating and cooling system's layout, including air flow direction and vent proximity to windows, is vital. Adjusting vent direction or using diffusers to avoid direct air flow onto the glass can create a stable environment for window film application.

Careful management of heating and cooling vent locations and orientations is key to minimizing thermal stress and maximizing the window film's benefits without risking the window's structural integrity.

At Flexfilm, we strive to offer comprehensive support and guidance; however, we cannot account for every unique variable in each individual project. Consequently, Flexfilm assumes no responsibility for issues arising from incomplete assessments or improper installation practices.

Shipping

Orders placed by 12:30 PM CST will be shipped out the same day. Orders placed after this time will be shipped on the next business day. We offer both standard and expedited shipping options within the United States. Exclusions apply.

Enjoy free shipping on orders over $750.

United States Shipping Options (Restrictions may apply):

- UPS® Ground

- UPS 3 Day Select®

- UPS 2nd Day Air®

- UPS Next Day Air Saver®

- UPS Next Day Air®

- UPS Next Day Air® Early

For more details and restrictions, please refer to our full shipping policy.

Returns

Films

- 30-day return policy.

- Buyer covers return shipping (deducted from refund if originally free).

- Up to a 20% restocking fee.

- All materials must be returned.

- Used rolls may receive a partial refund.

Pre-Cut Patterns

- No returns or refunds for custom films.

Tools & Equipment

- All sales are final.

- We replace wrong or defective items at our expense.

- No refunds for buyer’s remorse, misuse, or damage from lack of skill.

Plotters

- 30-day return if in re-sellable condition and original packaging.

- Overseas customers pay return shipping.

- Up to a 20% restocking fee may apply.

For more details and restrictions, please refer to our full return and refund policy.

Glass Safety Assessment

We offer professional-grade flat glass films designed for experienced installers. However, we’re unable to determine which specific Flexfilm product is safe for your particular window or glass type. Because we operate online, we don’t have access to the full range of variables needed to make an accurate, case-by-case assessment.

We strongly recommend consulting a local professional installer who can evaluate your glass in person. For liability reasons, we only provide official film-to-glass approvals to Flexfilm Dealers.

That said, you're welcome to reference our glass compatibility chart and supporting materials to help guide your decision—but please note that we cannot make a final recommendation ourselves.

Unprofessional or DIY Installation

Please be aware that applying our flat glass film through unprofessional or do-it-yourself (DIY) methods does not come with a guarantee of success or assurance against potential future complications. While DIY installation might seem cost-effective and convenient, the absence of professional expertise can lead to improper application. This might result in issues such as bubbles, peeling, uneven tinting, performance discrepancies, or even damage to the glass itself. Furthermore, any future problems arising from a non-professional installation might not be covered under our product warranty. To ensure the best results and maintain your product warranty, we highly recommend opting for installation by a qualified professional. This approach not only secures a successful outcome but also safeguards against the risk of avoidable issues down the line.

Got questions about our flat glass films?

We’ve got answers! Our FAQ section covers everything you need to know—from selecting the right film to making sure it’s safe for your glass. Installing flat glass film can take a little extra planning upfront, but doing your homework can save you time, money, and potential headaches later. Dive in and get the info you need to make your next installation a success!

Get more answersIs architectural flat glass film applied on the outside or inside of a window?

That depends on the type of film you’re installing. Most of our flat glass films are designed to be applied to the inside of the window to ensure maximum durability and performance. Here’s a quick breakdown:

- Dualflex dual reflective film: inside

- Chromoflex silver reflective film: inside

- Sputterflex sputtered film: inside

- Panashield/Nanoshield ceramic film: inside

- Safetyflex safety and security film: inside

- Specialty/decorative: inside

- Vandalflex anti-graffiti film: outside

Why is architectural window tint often reflective and shiny, resembling a mirror?

A common question we hear from customers is: "Do you have an architectural window film that's non-reflective but still rejects solar energy?" This is a great question, and the answer requires a bit of understanding about how different window films work.

Why Are Traditional Flat Glass Films Reflective?

Most traditional flat glass films, like our Dualflex, have a reflective appearance because they are designed to manage solar energy by literally reflecting it away from the window. This reflective quality helps to reduce heat gain inside the building, improve energy efficiency, and protect interiors from harmful UV rays.

Reflective films are effective for:

- Heat Rejection: By reflecting solar energy, they help keep the interior cooler and reduce the load on your cooling systems.

- Glare Reduction: Reflective films can also reduce glare, making indoor spaces more comfortable.

- UV Protection: They block a significant amount of UV rays, helping to protect your furnishings and floors from fading.

However, some customers find the reflective aesthetic less desirable, especially for homes or buildings where a more subtle look is preferred.

Non-Reflective Options: Ceramic Window Films

If a non-reflective appearance is what you're after, ceramic window films, like our Panashield, might be the solution. These films provide heat rejection and UV protection without the mirror-like finish of traditional reflective films. However, they work differently than standard flat glass films.

Ceramic Films and How They Work:

- Absorption, Not Reflection: Unlike traditional flat glass, like Dualflex, films that reflect solar energy, ceramic films are designed to absorb it. This technology is similar to how automotive window films work. By absorbing solar energy, ceramic films can still reduce heat and block harmful UV rays.

- Sleek Appearance: Ceramic films, like Panashield, offer a non-reflective, natural look that is often preferred for residential and commercial projects where a less noticeable film is desired.

The Catch: Use Ceramic Films with Caution

While ceramic films are an excellent option for those looking for a non-reflective appearance, they do come with some considerations. Since they absorb solar energy rather than reflect it, they can put more stress on the glass. This is especially important to consider for certain types of glass installations:

- Glass Type Matters: Ceramic films are repurposed from automotive films and aren't specifically designed for architectural use. The absorption of heat can create thermal stress, particularly on larger or more sensitive glass surfaces.

- Consult a Professional: Before applying a ceramic film to flat glass, it's crucial to evaluate the glass type, thickness, and location. Some glass types, such as certain double-pane windows, may not be suitable for films that work primarily through absorption.

The Bottom Line: Finding the Right Balance

If you're looking for a non-reflective window film for your flat glass project, Panashield or Nanoshield can be a great choice. They offer a sleek, subtle appearance while still providing heat rejection and UV protection. However, they do require careful consideration and professional assessment to ensure they are a safe and effective option for your specific glass type.

For those who are open to a slightly reflective finish, traditional flat glass films, like Dualflex or Chromoflex, offer a proven solution for heat rejection without the need for detailed glass assessment.

Need Help Choosing the Right Film?

If you’re unsure which film is best for your project, we’re here to help. Our team can guide you through the options and ensure that you select a film that meets your aesthetic preferences while keeping your glass safe and your space comfortable. Shop our architectural flat glass films here!

What is one-way daytime privacy, and how does window film achieve this?

As the owner of Flexfilm, I understand the increasing demand for one-way privacy in both residential and commercial settings. Privacy is not just about seclusion; it's about maintaining an open, light-filled environment that enhances comfort without compromising security. Let me explain how our window films, including popular options like Dualflex and Chromoflex, achieve this balance through advanced technology.

How One-Way Privacy Works with Our Films

- Light Differential: The magic of one-way privacy lies in the differential light levels between indoor and outdoor settings. The side exposed to more light becomes reflective. During the day, this phenomenon makes it difficult for anyone outside to see in, while those inside can still see out clearly.

- Reflective Films: Our films like Dualflex and Chromoflex capitalize on this by incorporating a reflective aluminum layer. This enhancement mirrors the brighter external environment, effectively turning your windows into mirrors from the outside during daylight, thereby safeguarding your privacy.

- Interior Visibility: Despite the mirror-like exterior, visibility from the inside remains unaffected. This is thanks to the carbon layer in films such as Dualflex, which absorbs some solar energy and reduces glare, ensuring that the interior remains comfortable and visually accessible to those inside.

Daytime versus Nighttime

One-way privacy with reflective window films functions effectively during the daytime by using the natural light differential to create a mirrored effect on the exterior, preventing outside views while maintaining clear visibility from within. However, at night, this privacy benefit diminishes as the interior lights overpower the darkness outside, reversing the effect and allowing visibility into the space. To maintain privacy after dark, additional solutions like curtains, blinds, or smart glass may be necessary.

Daytime Privacy:

- Reflective window films create a mirrored effect on the exterior, leveraging natural light to block outside views.

- Interior visibility remains clear, allowing occupants to see out without being seen.

Nighttime Privacy:

- The privacy effect diminishes when interior lights are on, as the light differential is reversed.

- Visibility into the space from the outside increases, making additional privacy solutions like curtains, blinds, or smart glass necessary.

Benefits of Installing One-Way Privacy Films

- Daytime Privacy: These films provide excellent privacy during daylight by creating a mirrored effect on the exterior side of the glass. This setup blocks external views into your building while maintaining your view outward.

- Glare Reduction: Our films not only enhance privacy but also mitigate solar glare, which is vital for reducing eye strain and improving comfort in brightly lit conditions.

- Energy Efficiency: By reflecting solar energy, our one-way privacy films help maintain cooler indoor temperatures, reducing the need for air conditioning and lowering energy costs.

- Aesthetic Appeal: With a sleek, modern finish, our films offer a stylish upgrade to any property façade, be it a residential home or a commercial building, enhancing overall curb appeal.

Ideal Applications for One-Way Privacy Films

- Office Buildings: Where confidentiality is paramount.

- Residential Homes: Particularly in densely populated areas where privacy from neighbors or passersby is essential.

- Glare-Sensitive Environments: Ideal in settings where reducing sunlight glare is as important as enhancing privacy.

At Flexfilm, we pride ourselves on providing versatile and effective solutions like Dualflex, Chromoflex, and Sputterflex, which not only assure one-way privacy but also bring additional benefits of solar control. Whether you're aiming to boost residential privacy or secure a commercial premises, our films are tailored to meet diverse needs while exemplifying industry-leading technology.

How do I help a customer choose the right film?

The triangle graphic is a highly effective visual tool that simplifies the decision-making process for customers choosing flat glass films. It enhances understanding by clearly outlining key factors—Solar Performance, Glass Safety, and Customer Problems—which helps customers easily identify their priorities. This not only engages customers more deeply but also improves communication, allowing for personalized recommendations and a streamlined sales process. Additionally, the graphic builds trust by demonstrating how each choice aligns with their needs, boosts confidence in their decisions, and serves as a valuable educational and marketing tool. Overall, this approach promotes efficiency, customer satisfaction, and long-term loyalty.

COMPONENTS OF THE TRIANGLE

The triangle includes three critical points:- Listen to Customer and Identify Problems: The apex of the triangle emphasizes the first step in our customer engagement process. By actively listening to our clients, we gain a deep understanding of their needs and the specific challenges they face with their current window solutions. This step is crucial as it sets the direction for the entire solution process.

- Maintain Glass Safety: The second point underlines the importance of safety in our product selection. Before recommending a film, we thoroughly assess the potential impact on glass safety. This includes evaluating risks like increased heat absorption that could potentially weaken the glass and cause breakage or seal damage. Ensuring the integrity of the glass is a foundational concern that protects both the property and the occupants.

- Solar Performance: The final point directs us to choose the most suitable window film technology that addresses the identified issues effectively. With options ranging from Dualflex and Chromoflex to Sputterflex, we determine which film offers the best performance in terms of heat reduction, glare control, privacy, and aesthetic value, thereby fulfilling the customer’s needs at the highest level.

HOW TO USE THE TRIANGLE

This triangular model is not just a visual aid but a guide for operational excellence. Here’s how to use it:- Start at the Top: Begin every customer consultation with an open dialogue. Encourage customers to describe their situations and what they hope to achieve with window film. This detailed understanding is critical in guiding the subsequent steps effectively.

- Assess Safety Needs: Once the customer’s needs are clear, evaluate the technical aspects concerning glass safety. Consider the structural characteristics of the windows and other physical conditions that could affect film performance. This ensures that any film recommended will not compromise the window’s integrity.

- Make an Informed Selection: With a thorough understanding of the customer's needs and safety considerations, move to select the ideal window film. Use your expertise to match the problem with the most effective film technology from our range, ensuring that it aligns with both performance expectations and aesthetic preferences.

BENEFITS OF USING THE TRIANGLE

- Comprehensive Service: This model ensures a holistic approach to customer service, addressing all essential aspects from personal needs to technical safety.

- Enhanced Customer Trust: By systematically addressing each point on the triangle, we build stronger trust with our clients. They feel heard, safe, and appropriately served.

- Improved Decision-Making: The triangle acts as a checklist that helps consultants avoid oversights and make better, informed decisions that are tailored to each customer’s unique situation.

What's the difference between dry and pressure sensitive adhesive?

Dry Adhesive (CDF Adhesive)

Characteristics:

Activation Required: Dry adhesive is non-sticky to the touch and requires activation with a slip solution during installation.

Chemical Bonding: Over time, it undergoes a chemical bonding process with the glass surface, which gradually reveals an underlying pressure-sensitive layer.

Benefits:

Ease of Installation: Its non-sticky nature before activation allows for easier handling and adjustment on large windows, making it especially useful for architectural applications where precision is key.

Contamination Resistance: Less prone to contamination because it can be easily rinsed and re-applied during the initial installation phase without compromising the adhesive's effectiveness.

Pressure Sensitive Adhesive (PS Adhesive)

Characteristics:

Immediate Bonding: Inherently sticky, it bonds instantly to surfaces upon contact, requiring no activation.

Versatility: Suitable for a wide range of applications, including automotive and architectural tinting, due to its strong, immediate adhesion.

Benefits.

Rapid Application: Ideal for quick installations, as it adheres firmly and quickly to the window surfaces without the need for a lengthy curing process.

Curved Surface Compatibility: The instant stickiness is particularly advantageous for curved or contoured windows common in automotive applications but can also benefit architectural projects with similar challenges.

Comparative Overview

While both adhesives are used in architectural window tinting, Dry Adhesive is often preferred for larger, flat glass surfaces where precision and the ability to manage contamination are priorities. Its delayed bonding process allows for adjustments during application, making it user-friendly and forgiving during the installation process.

Pressure Sensitive Adhesive, on the other hand, offers the advantage of instant adhesion, which can be beneficial in situations where quick application is necessary or for windows with complex shapes that require the film to bond immediately to avoid misalignment.

Ultimately, the choice between dry adhesive and pressure-sensitive adhesive depends on the specific requirements of the architectural window tint project, including the type of windows being tinted, the installer's preference for handling and application techniques, and the desired outcome in terms of appearance and performance.

Do I need to consider shading before installation?

Understanding the nuances beyond basic film-to-glass compatibility is key for successful window tinting, especially considering the impact of external shading. Shading from trees, buildings, or other structures can change throughout the day, creating a risk of thermal fracture where shaded and sunlit areas of the glass meet. This can increase the likelihood of the glass breaking due to thermal stress.

To avoid such issues, a detailed evaluation of the window's exposure to light and shade over the day is essential. This helps in choosing the right tinting material that suits the window's thermal conditions, preventing potential damage. Consulting our graphic below can also highlight risky shade patterns, aiding in effective tint planning. These steps ensure the longevity of the tinted window while keeping the building's occupants safe and comfortable.

Should I consider window framing before installation?

The choice of window framing is crucial for the safe application of window film, as it affects how well the glass can handle thermal expansion from sunlight absorption. Framing systems with flexible and strong materials like rubber gaskets, aluminum, steel, or vinyl are suitable, accommodating glass expansion without causing damage.

In contrast, rigid frames, such as those made from concrete or using sash designs, may increase the risk of glass cracking or breaking under thermal expansion, particularly with the added layer of window film.

The sealant's condition also matters; over time, sealants may harden and lose elasticity, making them less able to cope with the glass's expansion and contraction, thus raising the risk of failure. Meanwhile, resilient sealants can adjust to these changes, decreasing damage risk.

The color of the outdoor glazing stop is another consideration; darker colors absorb more heat, adding thermal stress that could worsen expansion issues, particularly in directly sunlit windows. Moreover, the design of the indoor structural pocket must allow for adequate glass expansion to avoid increased pressure and potential breakage.

In essence, successful window film installation on flat glass requires evaluating the framing system, sealant condition and type, outdoor glazing stop color, and the indoor structural pocket design. These factors determine the window's capacity to withstand thermal stress from the film, ensuring a secure installation.

Should I consider where heating and cooling vents are located before installation?

The location and orientation of heating and cooling vents are crucial for the safe and effective use of window film on flat glass surfaces. Vents directing air towards the glass can cause temperature variations, potentially leading to thermal stress. Heating vents can create hot spots by warming a cooler glass surface, while cooling vents can induce thermal shock by cooling a heated glass surface. These temperature changes, especially under the added stress from solar energy absorption and window film, can compromise the glass and film's integrity.

Positioning vents away from the glass helps maintain a consistent temperature across the window, reducing thermal stress risks and supporting the durability of the glass and film. Evaluating the heating and cooling system's layout, including air flow direction and vent proximity to windows, is vital. Adjusting vent direction or using diffusers to avoid direct air flow onto the glass can create a stable environment for window film application.

In essence, careful management of heating and cooling vent locations and orientations is key to minimizing thermal stress and maximizing the window film's benefits without risking the window's structural integrity.

Are there any environmental factors I need to consider before installation?

Design Winter Temperature is crucial for choosing the right window film, as it must endure the local minimum temperatures without losing effectiveness or damaging the glass. Films not designed for the locale's winter conditions might become brittle or fail to insulate properly.

Altitude affects window film due to changes in barometric pressure. At higher elevations, lower air pressure can increase stress on double-pane windows, potentially leading to damage when combined with the thermal effects of window film. Selecting a film that can withstand these pressures is vital.

Adjacent Reflecting Surfaces, such as water, other buildings, or snow, can increase sunlight and heat reflection, raising the risk of thermal stress on the glass. It's important to consider these factors by choosing films with high heat rejection or altering the environment to reduce reflection, ensuring the film's effectiveness and the glass's integrity.

What should I know about low-emissivity windows?

When installing window film on Low-E (low-emissivity) windows, it's crucial to consider several factors due to Low-E glass's special features designed to improve energy efficiency by reflecting infrared light and retaining heat. Key considerations include:

- Compatibility with Low-E Coatings: Choose a window film compatible with the Low-E coating to maintain its energy-saving benefits. Some films can enhance, while others might undermine, these properties.

- Thermal Stress Risk: Adding film can increase thermal stress, potentially causing glass breakage due to temperature differences across the glass surface. Select a film that manages heat transmission without creating significant thermal imbalances.

- Warranty Considerations: Ensure installing window film doesn't void the window's manufacturer warranty. Check warranty terms and consult with both window and film manufacturers.

- Visual Aesthetics and Light Transmission: The addition of window film can alter window appearance and the amount of natural light entering. The impact on building aesthetics and interior lighting should be considered.

- Energy Efficiency Goals: Aim for a window film that complements the Low-E glass's energy efficiency, enhancing without compromising its functionality.

Consulting a professional installer experienced in both Low-E glass and window film is recommended to navigate these complexities, ensuring the film supports the window's performance and the building's energy efficiency and comfort effectively.

Downloadable

Informational Booklet

Discover everything you need to know about our products. Our digital informational booklet includes comprehensive product details, specification data, glass compatibility information, and more. Download now to make informed decisions and find the perfect solution for your needs.

Download PDFSee Our Films in Action✨

@flexfilmtint

Don’t just take our word for it—check out the real-world projects our awesome partners have pulled off with our products! Follow us for fresh inspiration, and see how our solutions can level up your next DIY project or even boost your shop’s game. You might even be our next feature—just tag @flexfilmtint on Instagram or Facebook!

What Our Partners Say

Dennis Klotz

Flexfilm is the King!

"Ive been setup with Flexfilm for almost a year, and I wont go back to any othe rproduct. I have use them all in copious amounts, security, hurricane, solar and architectural. Flexfilm is the King!"

Craig Haney

Extremely Happy With The Final Result

"To be honest I am extremely happy since switching to Flexfilm. As an installer I think it is a very high quality product and from my customers stand point they are extremely happy with the final result too."

Shawn Davis, Davis Window Tinting

Love The 30% Terraflex

"Love the 30% Terraflex I used today for the first time. Metered spot on for matching the factory tint."

Sean Wahlberg

Flexfilm Is The Best Hands Down

"Flexfilm is the best hands down for the prices and service. You can't find anything better out there..."

Preston Raber, RAB Kustoms

The Tint Works Amazing

"This company is great to work with, and the tint works amazing!"

Zane Wilson

Never Had A Problem

"I have been using your film for almost 7 years now and never had a problem."

Ryan Mclane

Definitely A Go To

"Works great! Definitely a go to for me. As a newbie I have enjoyed how easy it is to work with."

Bradley Jones, The TintPlug

Shrinks Like A Dream

"Been using it for 2+ years and I love it shrinks like a dream and I have never had a problem with it at all."

Terrance Garnto

I'm With Flexfilm Now

"I've used most of the industry leaders. I'm with Flexfilm now"

Zach Muralt

Absolutely Love How It Works

"Started using Terraflex this week at Tint Conditions Window Tinting absolutely love how it works. Very impressed"

Matthew Waite

Amazing and Outta This World

“Hey I’ve been using y’all’s product for almost a year now and lemme tell y’all highly impressed! Terraflex carbon is amazing and outta this world customers love it!”

Richard Remelius

Quickly and Easily Order Film

“Flexfilm allows me to quickly and easily order film and tools online with no phone calls or middle man. I also like the fact that you have your film performance data readily available on the website. I appreciate the usually fast shipping also.”

You may also like

Dealer Rewards

Start earning points that can be applied as store credit on your next online purchase.

Order Online 24/7

Shop our products online and check out anytime, 24/7, from anywhere!

Call To Order

Call us directly to place your order during business hours, Monday - Friday, 8:00 AM - 4:00 PM CST.